1.02.08

Kernplattensäge

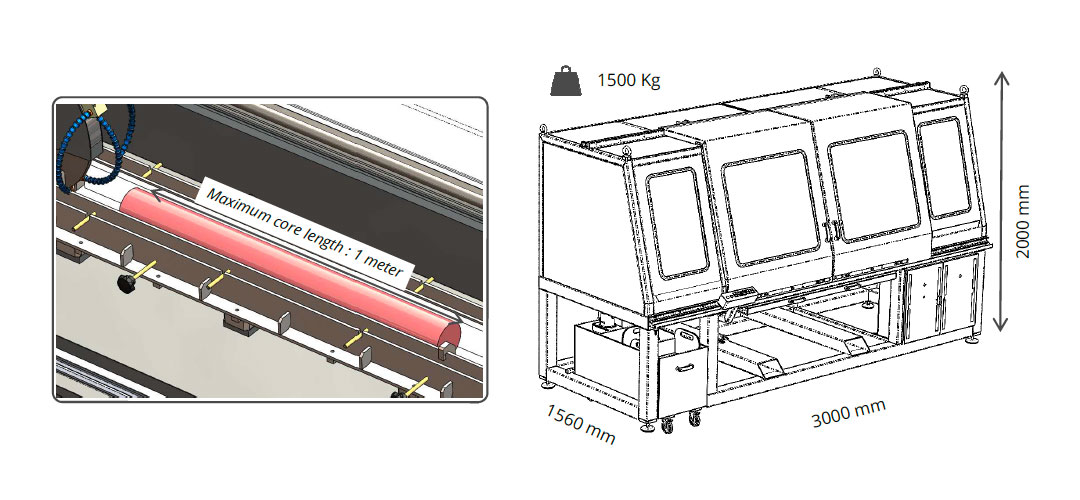

Semi-automatic, quick action, longitudinal geological core cutting machine, capable of cutting up to 1 metre length without fracturing, grooving or chipping. It produces a high-finished surface.

The 1 02 08 core cutting machine is a semi-automatic machine fitted with a diamond disc allowing the user to slice longitudinal and transverse drill-core sections.

While it is interesting to be able to cut a core sample longitudinally in order to examine its element and study their structure, this relatively easy operation for small core fragments becomes virtually impossible using normal methods (hand saw, ordinary diamond saw, etc.) as soon as the sample exceeds 40 to 50 cm in length.

Moreover, manual cutting causes irregularities in the cut and frequently fractures which considerably obstructs subsequent viewing of the sample.

Standard Equipment

-

Cutting system with 1 or 2 discs

-

a core vice for cutting longitudinal or transverse sections

-

It includes a set of servicing tools, but does not include the cutting disc.

Option

-

Vacuum cleaner with filter

-

Recycling system

Presentation

The core sample remains fixed, while it is the diamond disc – motor unit which moves from

one end of the core to the other.

This arrangement has made it possible therefore to place all the electrics and the automatic feed above the cutting area and protected from splashing of water and debris. The bottom of the machine forms a sump which collects the water and debris from the sawing operation. This is then drawn off into a large capacity tank before being drained away or recycled.

A water gun connected to the cooling circuit enables the machine to be cleaned.

A suction pump with electrostatic trap, makes it possible to extract and filter the water spray which is charged with core particles from the cut. The air is reintroduced into the unit without affecting the heating or air-conditioning of the area.

Core sample vice

Cutting unit

The grinding pressure is maintained whatever the hardness of the material encountered. This pressure is automatically adjusted while the machine is in operation.

The discs are protected by a casing. Abundant watering comes from nozzles mounted on hoses. Cooling, like the disposal of waste, is perfectly assured.

Automatic feed

At the end of the run, a stop ring halts the movement of the carriage. The drill core sample is thus cut from one end to the other without monitoring.

Characteristics

Electrical

-

Three phase current 400 V 50 Hz (60 Hz on request)

-

Spindle motor 9,2 Kw (1 500 tr/mn)

-

Forward movement motor 0,37 Kw.(0 à 15 tr/mn Feed from 0 to 2 m/mn)

-

Pump motor 0,15Kw.

-

Reinforced cabling

Cutting disc

-

∅ 300 – 350 – 400 mm

Wir sind für Sie da

Der persönliche Kontakt ist für uns besonders wichtig. Unsere Produkte sind so individuell wie Ihre Anforderungen. Gerne beantworten wir Ihre Fragen und freuen uns auf den Kontakt:

SCAN-DIA GmbH . Lütkenheider Straße 11 . 58099 Hagen

Telefon: +49 23 31 624 69-0